ultrasonic clamp-on

Flowmeters

We measure from the outside what is flowing in the pipe - The ultrasonic clamp-on flowmeters are cost-efficient flowmeters and suitable for retrofitting without process interruption. The volume flow of a wide variety of liquids and gases can be measured reliable. Almost independent of pressure, temperature, or viscosity.

FEATURES

How does an

ultrasonic clamp-on

flow meter work?

ATTRIBUTES

- The sensors of the meter series are available for pipelines from DN10 up to DN6500 (3/8" - 256").

- Clamp-on design for stationary or temporary/portable flow measurement

- Temperature range for standard sensors from -30 °C to +250 °C (temporarily up to 300 °C)

- Instrument version with IP 68 shear and Lamb ultrasonic sensors made of stainless steel for measuring gases

- Measuring accuracy volume flow: ±1 - 3 % of measured value, ±0.5 % of measured value (with field calibration)

- Two-channel equipment can save costs and time, as the flow measurement can be carried out either simultaneously on two separate pipes or on only one pipe in two-path mode.

- Display volume flow/mass flow

- Flow velosity range from 0.01 m/sec up to 25 m/sec

- Integrated data logger for up to 100,000 measured values and software for data evaluation

- Measuring functions (heat quantity/cold quantity), optional PT100 inputs for heat quantity measurement

- ATEX - Version, II 2G Ex de IIB T6 Ex-certification EPS 11 ATEX 1355 X

The measuring principle is based on the ultrasonic transit time method. To measure the flow rate, two ultrasonic sensors (clamp-on sensors) are mounted on the outside of the pipe. The ultrasonic signal of the sensors pass through the pipe and the medium both with and against the flow direction. The calculated difference in the transit time of two opposing signals is directly proportional to the flow velocity and can be displayed as a flow volume with the input of additional pipe parameters.

- Suitable for corrosive liquids and media with different viscosities

- Cost-efficient flow measurement of almost all electrically conductive and non-conductive liquids and gases

- No moving parts, therefore no wear and tear and minimal maintenance and care

- Installation directly on the pipeline without process interruption

- Free pipe cross section and no pressure losses

- Low investment costs. The sensors are installed directly on the pipe and high cost efficiency with increasing nominal pipe diameter

- Configuration according to customer requirements possible

- Communication options RS 485, Modbus RTU, Profibus PA and HART* compatible output, Analogue inputs for density, temperature and pressure compensation

- HART® is a registered trademark of the HART Communication Foundation

IN OUR PORTFOLIO

Flowmeters available from stock:

Portaflow 222

Portable Clamp-on Flow Meter

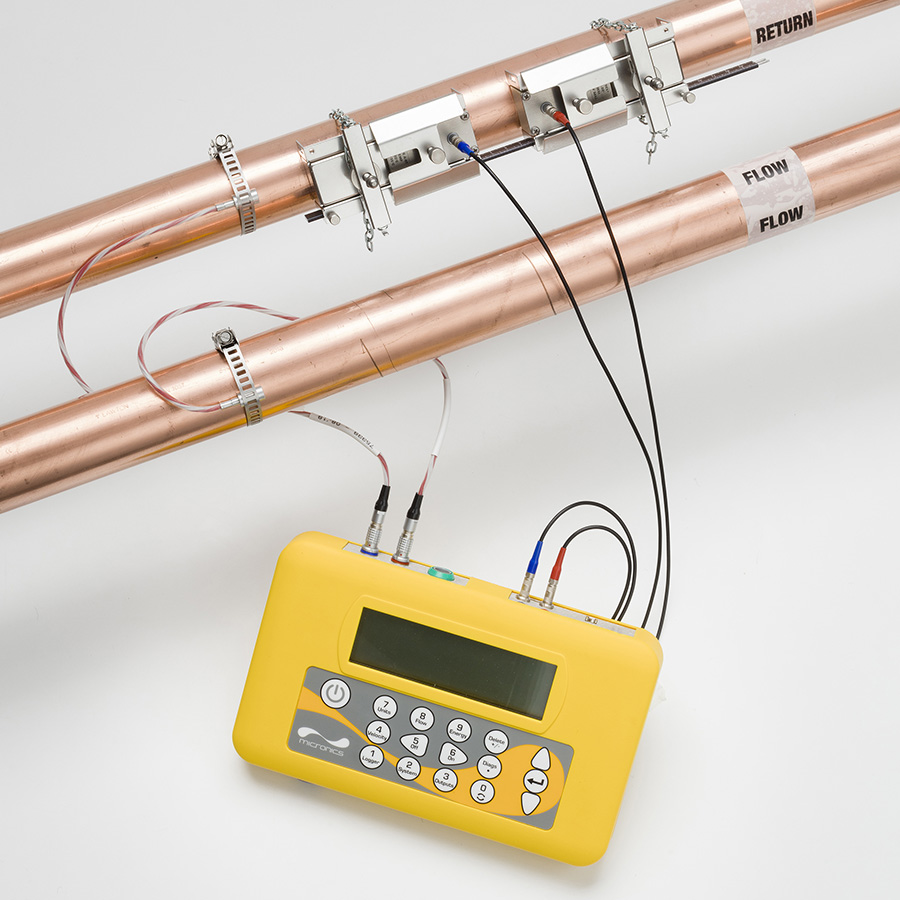

Portaflow 333

Portable Clamp-on

Flow & Heat Meter

UF3300

Fixed Clamp-on, HeatEnergy, Flow and Process Measurement Meter

U1000MKII-FM

Fixed Clamp-on, Ultrasonic

Flow Meter

U1000MKII-FM-WM

Clamp-on Flow Meter with Wall Mounted Keypad & Display

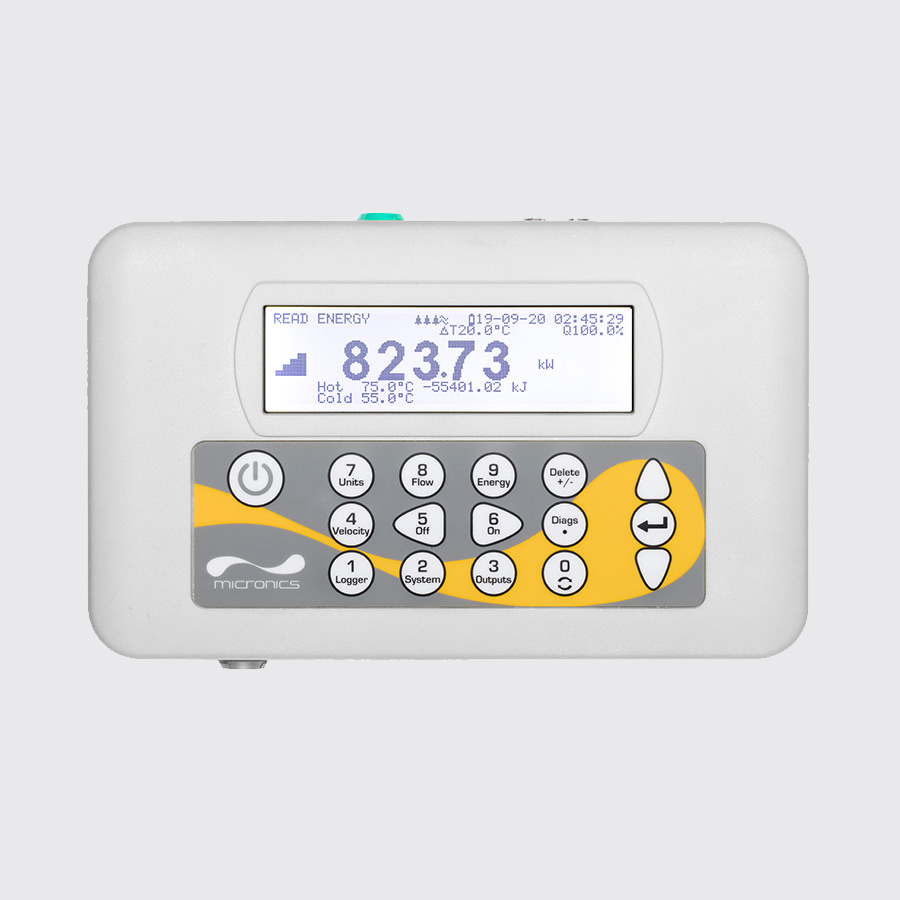

U1000MKII-HM-WM

Clamp-on HeatEnergy Meter with Wall Mounted Keypad & Display

Ultraflo UF3300

Fixed Clamp-on Flow and Process Measurement Meter

Ultraflo U1000MKII-HM

Clamp-on Heat MeterEnergy Meter

UX5000 ATEX / IECEx Approved

Clamp-on hazardous area Ultrasonic Flow Meter